Elevate your ROI with lifting equipment

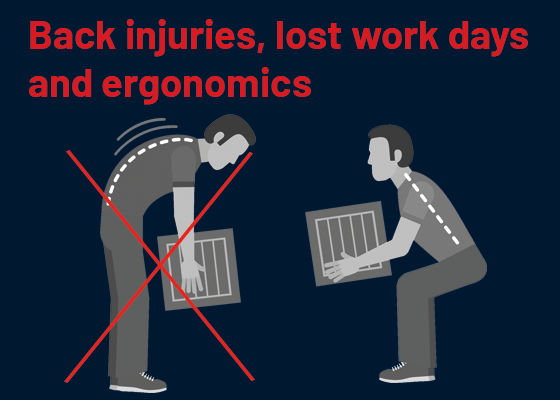

Work-related back and neck disorders are the most common occupational disease in Europe and accounts for almost 50% of all occupational reasons for absence. This has been estimated to cost between 0,5 - 2% of the gross national product in European countries. Workers in the food industry appear more frequently in the statistics for both minor and acute injuries and deaths (1). 75% of the injuries caused by manual lifting could be prevented. Therefore, we are looking at the ROI of lifting equipment (2).

ROI

ROI is an abbreviation for Return on investment. It is a way to calculate the expected profitability of an investment.

To calculate ROI, you divide the savings by the invested amount. It is only feasible if you can get greater output on the same amount of time or reduce your costs.

Better work environment at a lower cost

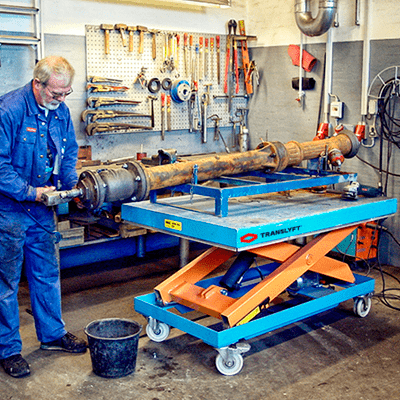

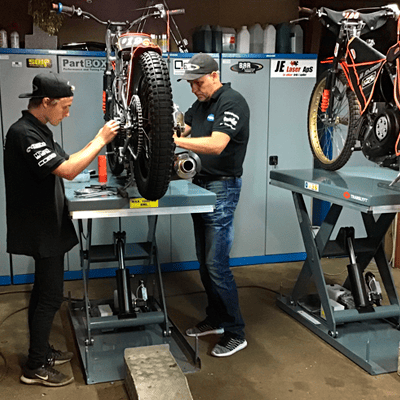

With any investment it is important to look at the value that the product adds to the business. There are two sides of investments you are making when purchasing lifting equipment. First there is the softer values like the health and safety of your employees to avoid back pain and injuries. And then there is the financial investment where you look at increased productivity, fewer injuries, and sick days. Both sides combined make it impossible to ignore that investing in lifting equipment is overall of great value to your business.

If we look closer at the benefits, they are due to many different aspects. When you have lifting equipment to ease the burden of lifting, bending, or twisting from your employees, it will make a difference in the increased performance level and can be measured in fewer sick days and injuries.

A lifting device will also reduce fatigue in employees which reduces mistakes and the risks of call back of products.

There is also an ergonomic benefit to ad. The ergonomic benefits of the lifting device improve worker morale and reduce work stoppages, medical claims, and absenteeism. More people will be able to occupy jobs when lifting equipment is made available making the selection of workers broader. A content work force is more loyal which has the benefit of fewer resignations and you therefore save the time and effort to train new employees (3).

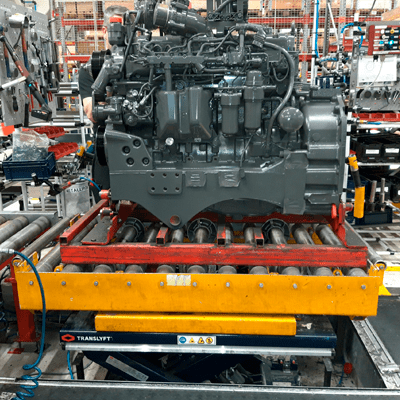

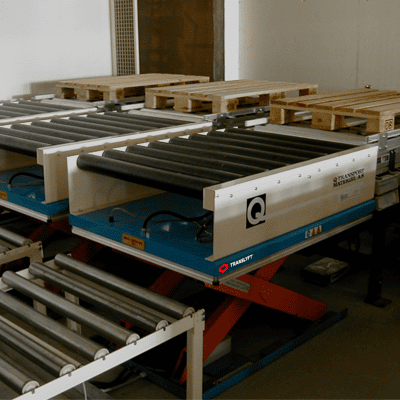

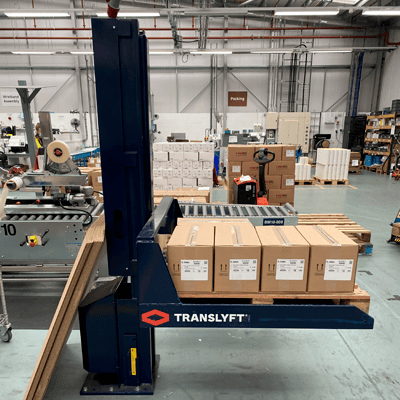

Lifespan is important

When considering the total cost of ownership of an ergonomic solution such as lifting tables it is important to consider the quality and thereby life span of the product. We regularly service TRANSLYFT lifting tables more than 20 years old, proving that our solutions are of good quality and stable which further improves the ROI of the product.

More is needed in food manufacturing

The food industry has a statistically higher rate of injuries compared to other industries. This also applies for acute injuries and deaths (4). Looking further into the numbers 30% off all acute injuries in the food and drinks industry are caused by manual handling and lifting (2). Many of the back injuries are caused by heavy lifting and twisting and the long hours with repetitive work is also affecting the numbers.

The cost of sick days in the food industry are astronomical. In the UK, the average number of sick days for people employed in the food industry is 6,3 days. The CIPD, HSE and Office for National Statistics have concluded that the average cost of absence to your business is €622 per employee per year. And then you just need to multiply this number with the number of employees. 100 employees equal a staggering €62.200 per year (5).

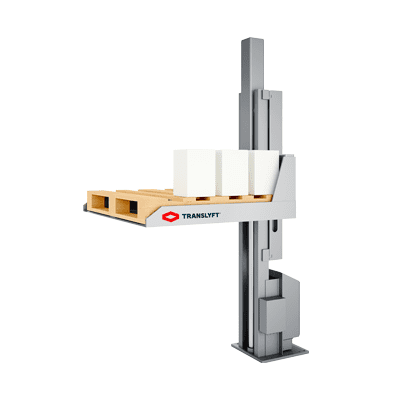

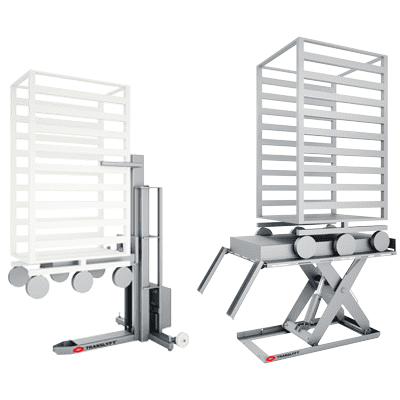

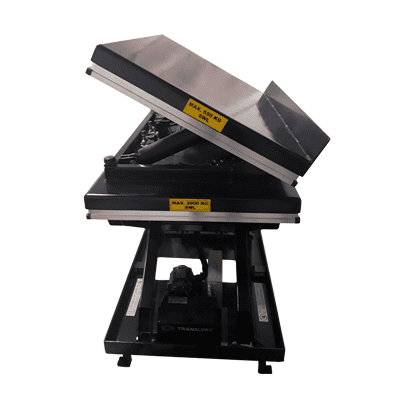

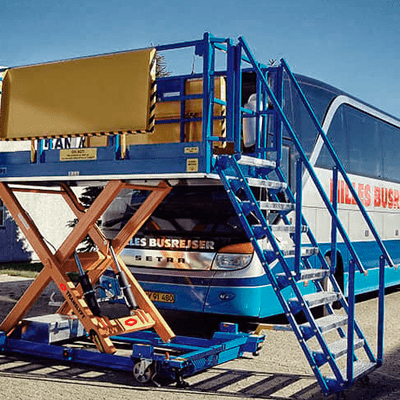

As mentioned earlier a lot of these accidents can be avoided with assisting equipment and machines developed to ease lifting. This could be mobile lifters, lifting tables, swing loaders, hoists, manual high lifter and so on.

According to the U.S. and EU regulations it is the employer’s responsibility to identify physical risks and eliminate them or provide aids to make handling actions safe (6).

Lift your hygiene as well

Hygiene in food production, has been an issue which has gained a lot of attention worldwide in recent years. At TRANSLYFT we experience an increased focus on improving the hygiene during the food processing, as this has proven more cost effective in a long-term perspective.

We are experts in stainless steel solutions and have even developed a sensational new concept called TRANSLYFT Hygienic Design which is currently being patented. This line of lifting tables has made cleaning of the table easier and you save up to 50% of time water and detergent in the cleaning process further adding savings to the ROI. A higher level of hygiene can also be a factor to avoid contamination of foods leading to fewer revocations of food batches.

Click here to find out more about our Hygienic Design lifting tables .

For questions or input please contact us

The Translyft team is trained to help you find the perfect solution for your workspace. Often a visual image of the location makes it easier to understand the unique challenges for the specific workstation. Therefore, we offer videoconferences or visits to give you the best consultation.

Call us at +45 9886 4900 or send an e-mail to sales@translyft.com

Sources

1: US National Library of Medicine National Institutes of Health

3: Assembly Mag

4: US National Library of Medicine National Institutes of Health

5: IPRS Health

6: 2Lift