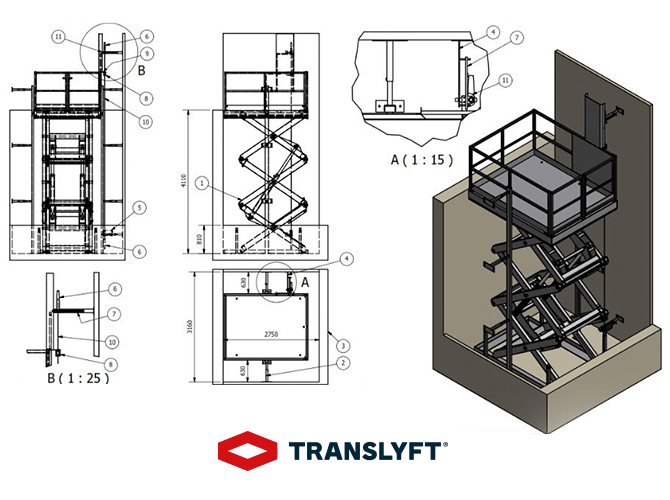

Lyftlösning för lastkaj förbättrar säkerhet och effektivitet

Lyftlösning minskar tid och risk

Ett företag inom hemutrustning som importerar varor i fraktcontainrar behövde en alternativ lösning för lossning. Vår lösning skapade en säkrare arbetsmiljö med bättre ergonomi och minimerad fallrisk.

Coopers of Stortford är en brittisk återförsäljare inom hem och trädgård, känd för praktiska och innovativa produkter med över 30 års tradition och ett urval av över 15 000 produkter. De betjänar kunder i hela Storbritannien via katalog, online och i butik.