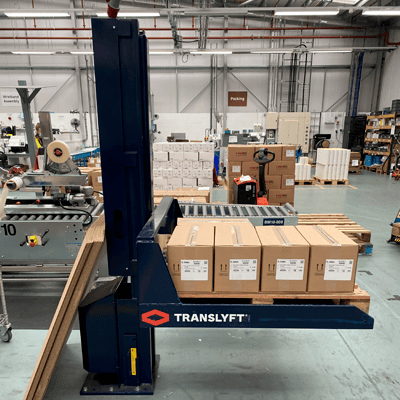

Custom pallet lifter optimizes logistics and ergonomics at DEHN SE

DEHN needed an ergonomic pallet lifter for 30 new production workstations in new plant. Translyft delivered a custom, width-optimized solution that enhanced both efficiency and worker comfort.

The challenge

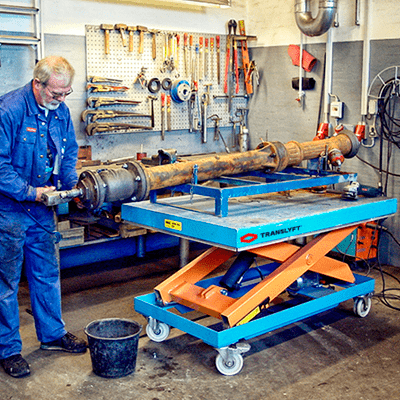

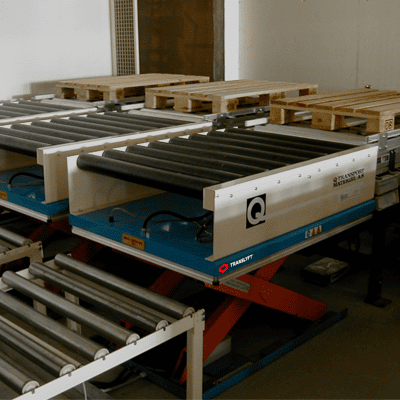

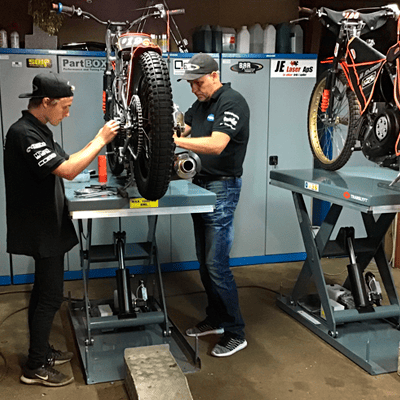

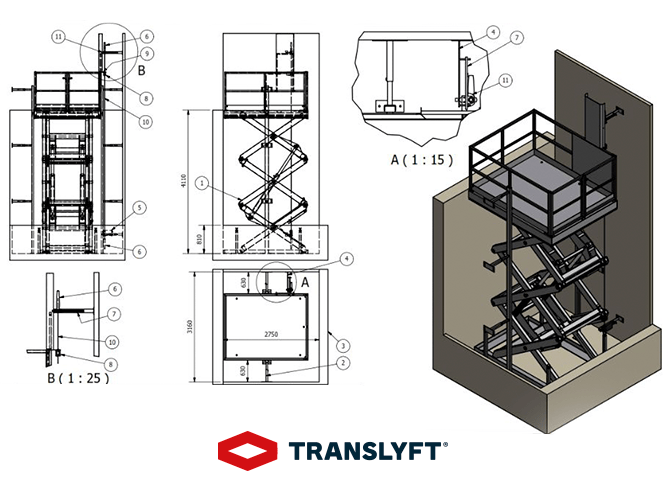

DEHN SE, a leading, international family-owned electrical engineering company based in Neumarkt, Germany, has significantly expanded its production capacities with the construction of a new plant. An important project was the implementation of 30 new packing stations on the shop floor. To enable fully automatic supply from existing Automated Guided Vehicles (AGVs), DEHN needed ergonomic U-shaped lifting tables for each station. However, standard scissor-lift tables presented a disadvantage: their 100 mm side protrusion over pallets impacted ergonomics, adding unnecessary strain to worker movement and positioning. DEHN, therefore, reached out to Translyft, seeking an ergonomic lifting solution with a compact footprint.

The solution

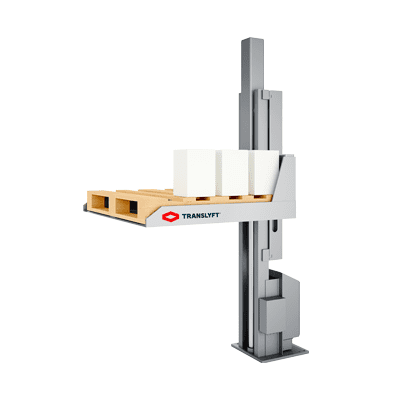

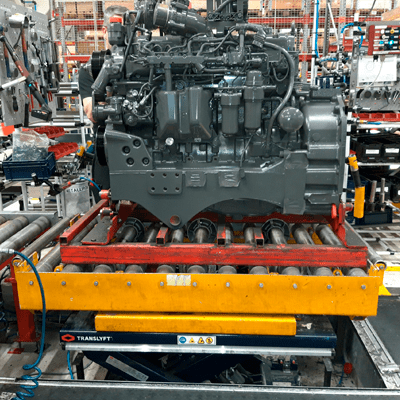

Translyft proposed its TSL model, featuring a compact, width-optimized design. Since DEHN’s operations did not require access to the platform's rear side – restricted by the lifting column – the TSL model provided an ideal load platform without compromising ergonomics. Translyft’s technology team collaborated closely with DEHN to refine this design, integrating features tailored to workplace safety.

Further customization involved the platform’s visual design to ensure it aligns with DEHN’s brand identity. The result was a coordinated red and grey concept that blends seamlessly into the production area, reinforcing DEHN’s brand image.

The result

Translyft built a prototype for DEHN’s team to test, - including operators, AGV coordinators, and safety personnel - to ensure the lifting solution met all functional, ergonomic, and safety standards. After successful testing and approval, DEHN commissioned the remaining TSL units, enabling ergonomic, efficient, and visually cohesive workstations across its production area.

The TSL platform design also allows workers to place their feet comfortably beneath the platform, improving posture and ease of movement during tasks, adding an extra layer of ergonomic support for the team.

"We are very pleased with the solution and proud to have a customized, well-functioning system," says Mr. Kürzinger, Deputy Plant Manager at DEHN. "The workers are happy with the system. It took some time to get used to handling the lifters, but after that, it was fully accepted."

This collaboration demonstrates Translyft's ability to deliver ergonomically optimized, space-efficient lifting solutions tailored to customer-specific needs in demanding working environments.