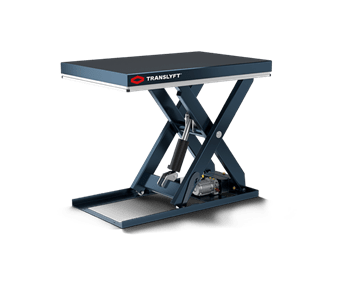

Low profile scissor lift table

Low profile scissor lift tables are particularly great for handling pallets or palletizing and depalletizing and working in places where a pit is not an option. This is due to their very low building height at around 85 mm. They ensure a consistent and ergonomically correct working height for the person performing the task. Beyond being ergonomically sound they also have a positive impact on efficiency as the strain of vertical movement eventually slows down the process speed.

Low profile scissor lifts are also very handy in places where the user does not want to make a pit in the floor, but still requires a very low closed height of the scissor lift table. This may be due to the fact that the item placed on the lift is quite tall or multiple items are stacked high, which requires a low profile scissor lift table to continuously ensure a good working height for the operator.