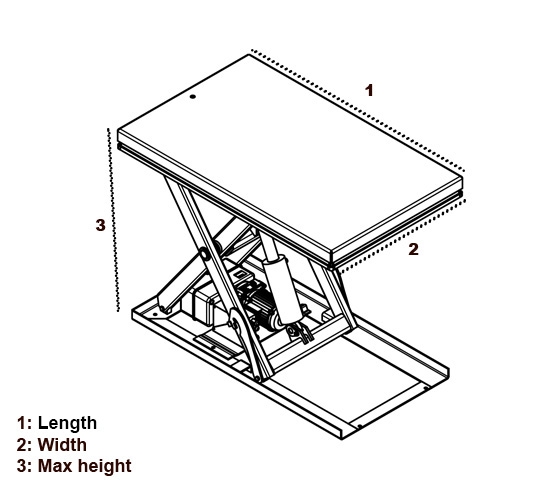

Get data sheet for single scissor lifting tables

Create your own customized solution tailored to your needs with our easy-to-use configurator

There are many lifting solutions out there. However, a scissor lift table has many benefits that you may not have been aware of.

TRANSLYFT can deliver spareparts to all our lifting tables.

Whether it is a cylinder, oil or wheel that needs to be changed, we have it in stock so we can send it to you quickly. Write to our spareparts mail or contact Michael at tel. +45 9647 4623

Did you not find a product that fit your exact needs? TRANSLYFT are experts in both small and large adjustments of our products so please do not hesitate to give us a call and hear more.

TRANSLYFT can manufacture most products in stainless steel, galvanized steel and painted. Read more about the three surface treatments here