Pallet elevator boosts access and OEE

Optimising Uptime at KP Components

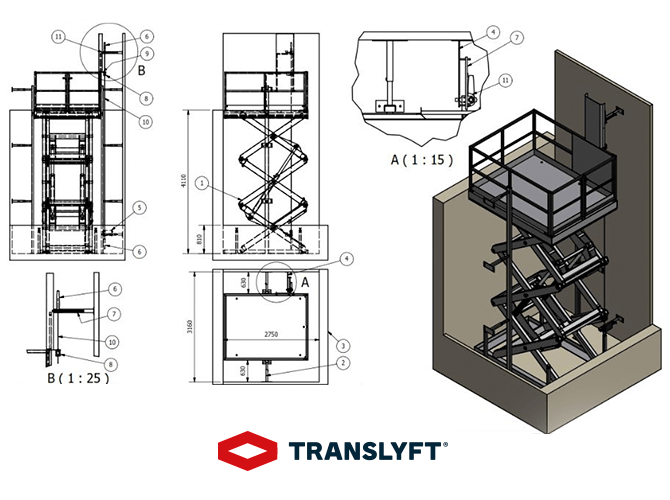

KP Components is one of Denmark's largest and most advanced machine manufacturers. KP Components manufactures hydraulic components for organisations all around the world, and the factory's machines operates 24 hours a day. Translyft's specially designed pallet elevator is currently assisting them in increasing their OEE (Overall equipment effectiveness).

KP Components is a leading Danish manufacturer specialising in precision-machined hydraulic components. With around-the-clock production and a focus on high-performance automation, the company supplies critical parts to industries worldwide.