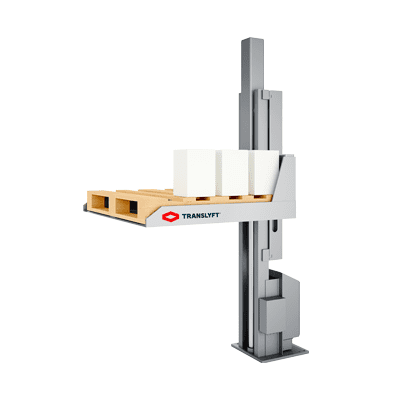

Material handling equipment

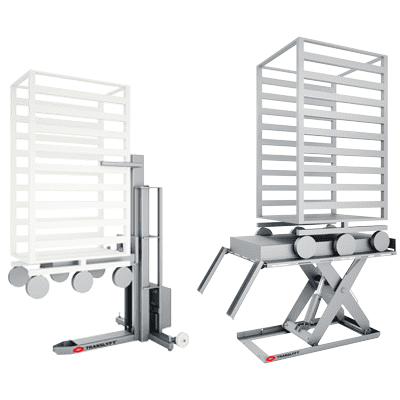

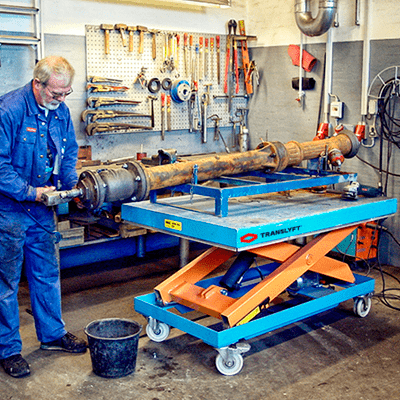

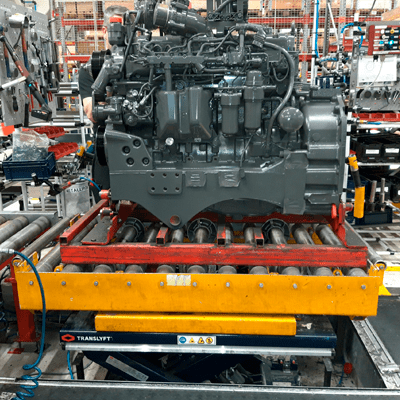

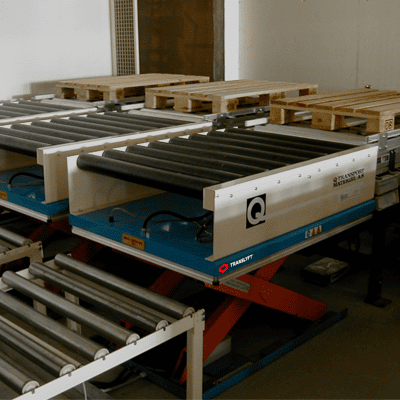

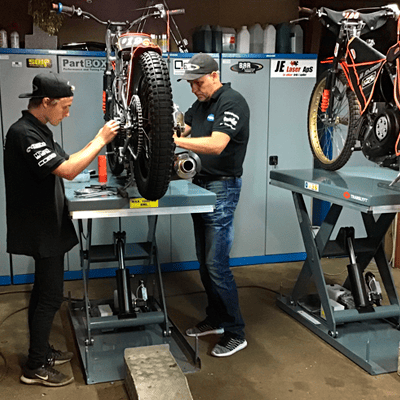

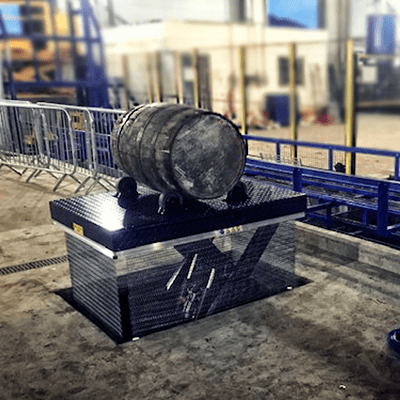

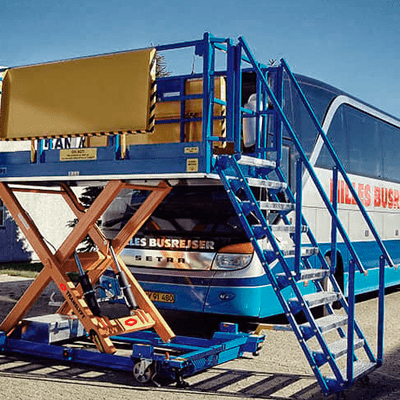

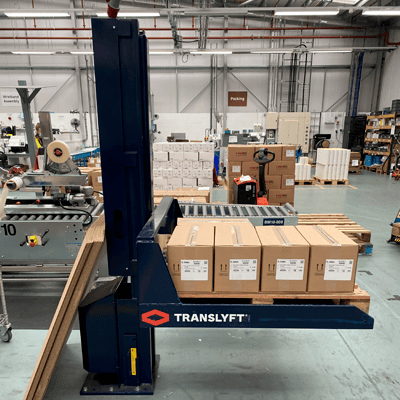

Material handling equipment is a mechanical equipment that has been proved to be useful in storage, control, movement and protection of various goods, materials and products. They complement the transportation process in transporting loads, process lines and areas where a crane is not possible to use.

Material handling devices are means of close transport with a limited range and intermittent traffic, used to transport loads throughout the process of manufacturing, distribution, consumption and disposal. They are a base for connection between elements of the production process in various industries. The task of the material handling equipment is to transport construction elements, different products or machines from one place to another, e.g. production hall or from a hall to the storage yard through unloaded areas.

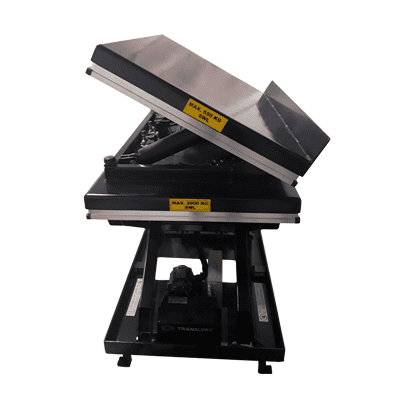

The capacity of a specific material handling device can vary between models as they are adjusted to the specifics of the process they need to handle. They can reach up to several hundred tons.

The material handling solutions help by restricting the application of the burdens associated with the material handling of contents, loads or materials, and facilitating those operations.