Lifting Table Types & Variants

Scissor Lift Configurations

Scissor lift tables offer a stable and space-efficient method for raising and lowering loads across various working heights. Their versatile design is suited for both standard and specialised industrial workflows.

Our product range includes compact single scissor lift tables, high-reach double scissor lift tables, and triple lift tables for extended vertical movement. For applications that require lateral stability or elongated platform travel, double horizontal lift tables are available.

In environments with limited space or where pits are not feasible, superlow lifting tables and low profile scissor lift tables provide efficient solutions with minimal closed height, enabling ergonomic access for loading and unloading.

Additional configurations include hydraulic single-scissor lift tables, static scissor lift tables, compact small scissor lift tables, and hydraulic scissor lift tables with electronic controls. Each model is engineered to meet performance requirements such as lifting precision, height limitation, or reduced footprint.

All TRANSLYFT scissor lift tables are built for reliable operation, seamless integration, and sustained performance in even the most demanding environments.

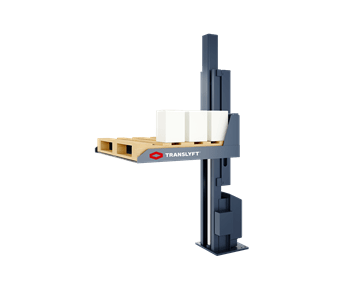

Manual & Mobile Table Options

For workflows that demand mobility and on-site adaptability, our mobile and manually operated lifting tables deliver essential flexibility. While all TRANSLYFT lifts feature hydraulic systems, manual control features and mobility kits such as wheelsets and brake systems make these tables ideal for dynamic environments.

We offer compact table lifts optimised for lighter loads and mobile workstation integration. With fixed or directional castors, these units provide dependable handling in packaging zones, assembly areas, or maintenance departments.

Manual scissor lifts offer straightforward operation when full automation is not required. Accessories such as handlebars, foot brakes, and foldable wheelsets enhance control and safety in shared or confined spaces.

Specialty Applications & Custom Engineering

Work Platforms

When working at height is a routine task, stability and safety are essential. TRANSLYFT lift tables can be adapted into ergonomic and secure work platforms, enabling operators to perform elevated tasks comfortably and efficiently.

Suitable for assembly lines, inspection stations, or technical service tasks, our lift table work platforms can be tailored to your specific height, space, and mobility needs. Adjustable portable work platforms improve posture, reduce fatigue, and accommodate varying operator heights and task demands.

For space-conscious setups, portable folding work platforms offer a compact alternative without compromising load capacity or stability. They can be relocated, stored, or redeployed with ease and are ideal for multi-use workspaces and flexible production areas.

We also provide specialised solutions like portable aerial work platforms for overhead maintenance, component access, and light installation jobs. These units offer safe elevation and accurate positioning for working at height.

Our work platforms can be equipped with essential safety features including handrails, secured access points, and tethering attachments. All models are designed with hydraulic precision and operator comfort in mind to ensure smooth integration into your workflow.

Solutions for Loading Bay Efficiency

Loading bays demand speed, resilience, and complete coordination. Our loading bay lifts are engineered to meet these needs. These solutions are developed specifically to address the height difference between loading trucks and the building floor, offering seamless transitions and high goods throughput.

Our lifts function as both lifting and bridging tools, making them ideal for transferring goods from vehicle to facility with minimal manual handling. Our loading bay scissor lifts are built to withstand demanding use and varied load types.

The loading bay lift tables are often used where there are no built-in docks, or where mobile and adjustable handling is necessary. In addition to loading bay lifts, we also offer dock levellers, ramps, and custom platform designs tailored for various vehicle heights and load types.

Each lift can be equipped with built-in safety features and can be customised to fit specific space constraints or logistics flows. Whether retrofitting or designing from the ground up, we ensure dependable and ergonomic material transfer at the dock.

Custom Solutions & Niche Use Cases

Not all lifting challenges fit conventional categories. That is why TRANSLYFT excels in designing custom-engineered lift solutions tailored to your task, industry, and operational environment. In fact, 9 out of 10 lifts we deliver are customised to a lesser or greater extent.

Whether you are lifting fragile components, working in unconventional spaces, or integrating lifting devices into specialised workstations, we develop the optimal mechanism for your use case.

Need to incorporate lifting into your production flow? TRANSLYFT designs and integrates both manual and automated systems, perfect for packaging stations, assembly lines, and modular work environments. Our capabilities include retrofitting lift tables with advanced control systems and mechanical structures to support unique motion, access, or operator requirements.

Want to customise your own lifting table? Our product builder allows you to configure your lift in an interactive 3D environment, giving you complete control over features and specifications. Try the TRANSLYFT builder tool to explore the full range of options available.

Stainless Steel & Hygienic Solutions

In sectors where hygiene and contamination control are critical, our stainless steel lifting tables meet stringent sanitary standards. TRANSLYFT provides stainless steel lift tables engineered for cleanroom, pharmaceutical, food processing, and medical-grade applications.

These stainless steel hydraulic lift tables are built to endure regular washdowns, resist chemical exposure, and maintain structural integrity, all while supporting your specific hygienic compliance requirements. We use acid-resistant components and smooth finishes to prevent residue buildup and enable thorough cleaning.

Whether you need a hygienic scissor lift table for a food-grade environment or a stainless steel lifting platform with specific surface treatments, we ensure that your requirements are met without unnecessary cost. Our consultants work with you to define only the features you truly need.

As with all TRANSLYFT solutions, stainless steel tables can be scaled and tailored. Whether your task requires XXL lifting capacity, oversized platform dimensions, or integrated hygienic features, we deliver precision-built solutions for your specific application.

Ergonomic, Tilting & Rotating Features

TRANSLYFT lift tables are engineered with ergonomics at the forefront. By allowing loads to be raised, lowered, tilted, or rotated into optimal positions, our ergonomic lift tables reduce the risk of repetitive strain injuries and boost productivity across workstations and production lines.

Our ergonomic product range includes tilting scissor lift tables that incline loads for easier access during sorting, assembly, or inspection. These are available in fixed-angle or adjustable formats, making them ideal for multi-task workflows.

For rotational access, turntable lifting tables allow smooth 360-degree rotation to reduce the need for manual repositioning. Options include centre-mounted turntables and motorised turntable lift solutions tailored for semi-automated or manual handling.

Additionally, conveyor-ready lift tables equipped with roller conveyors or rolling surfaces help facilitate directional transfer of goods. These are ideal for loading stations, packaging areas, or when merging manual work with conveyor automation.

We offer a wide array of accessories and options to enhance the ergonomics and utility of your lifting table. From anti-fatigue mats and side guards to advanced control panels, every component can be matched to your workflow. Contact our team for standard or bespoke ergonomic solutions.

Lifting Tables Built for You

At TRANSLYFT, we go beyond standard lifting equipment. We engineer lifting solutions that fit your exact needs. Each table lift is developed through a close consultative process, ensuring alignment with your environment, workflow, and performance goals.

Custom does not have to mean costly. Our flexible production and modular systems allow us to adapt standard lifting tables to meet your specifications and budget, without compromising quality or lead time.

Whether your focus is high-precision hydraulic lifts, safety-enhanced configurations, or seamless automation integration, TRANSLYFT delivers. Our proven expertise in scissor lift tables, ergonomic enhancements, and tailored configurations gives you the freedom to think beyond off-the-shelf equipment.

If you are ready to lift smarter, safer, and more efficiently, our team is here to guide you through the design and delivery of custom lifting tables that support your goals, today and in the future. Be sure to explore our product builder tool for a hands-on way to configure your solution.