You are welcome to contact us

Want to hear more? Get in touch with us by clicking the mails or phone numbers below.

Want to hear more? Get in touch with us by clicking the mails or phone numbers below.

A scissor lift table, or a lifting table, as it is also called, is a work table that can be raised and lowered to the desired position, thus making working with heavy elements more ergonomic and reducing the need for many repeated and manual lifts. It uses a straight-line upwards motion. A scissor lift is a safe and reliable solution that last for many years.

A lifting table has many nicknames such as lift table, scissor table or hydraulic lifter. The scissor reference comes from the fact that the table is constructed with two scissor arms that run parallel which gives a smooth movement.

Potential use of the lifting table includes warehouse, production line, construction site or any other location where lifting goods or people is necessary.

The table can be adjusted to perform under almost any working circumstances, whether your task requires the lifting table to work with assembly, welding or handling parts and components.

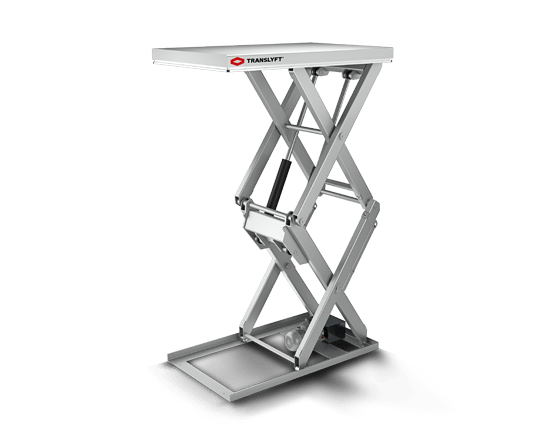

Our three main lines include: Silverline, standard product line and the hygienic design and are available in different materials: stainless steel, galvanized steel and painted. Read more here.

The tables comply with EN 1570 safety regulation, ISO 9001 and can be produced in ATEX if requested.

A lifting table raises or lowers things to the desired height for easy access and handling. They are frequently utilized in manufacturing, storage, and transportation facilities, as well as construction and warehousing sites.

A lifting table has several advantages, including being a safe and effective way to handle large items, reducing the risk of accident, and increasing production. By minimizing heavy lifting processes, you will see an increase in employee efficiency since they will be less exhausted and more content, resulting in fewer sick days.

In the long term, you save your employees' bodies from straining, lowering the chance of MSDs.

Lift tables are classified into three types: hydraulic, manual, and electric powered lifts (an electric lifting table is also called a spindle or a linear actuated lifting table).

A hydraulic lifting platform raises and lowers the platform using an electric motor with a hydraulic pump. Similarly, a manual lifting table also uses a hydraulic pump but it requires physical effort via a handle or a foot pedal to elevate the platform.

A linear actuated lifting table uses a spindle and a gear motor to elevate and lower the platform.

A lifting table consists of a base frame, the scissor, and a platform. Most systems use a hydraulic pump and an electric motor or manual labour motor to elevate the platform. An electric lifting table or a linear actuated lifting table uses a spindle and a gear motor to make the lift raise and lower the platform.

Simply set a pallet or other objects onto the lift platform, use the control box to elevate the lifting table to the best ergonomic work height. The best work height depends on the height of the person using the scissor lift. Working at the correct height positively influences the posture, health, and productivity of a worker, which makes a lifting table a good investment.

Lifting tables are mechanical devices for lifting and lowering large objects. They are frequently used to lift items in warehouses, factories, and other industrial environments. Hydraulics, electricity, or a combination of the two can power lifting tables. They are built to be safe and simple to operate, with features like safety trip bars, and emergency stop buttons to help prevent accidents and injuries. All lifting tables are built to lift or lower heavy objects to various heights. Lifting tables come in a variety of surfaces such as painted steel, galvanized steel or stainless steel.

There are many benefits of a hydraulic lifting table. Among other things, a lifting table is designed to with-stand heavy loads over many years. We have many customers returning to us asking for spare parts for scissor lifts that are more than 15 years old.

Basically, you use a scissor lift or a lifting table, wherever there are problems with heavy lifting, awkward working positions or height variations. You place an object or pallet on the lifting table and lift it to the ideal working height for the employee working at the table. At a production line, the employee can, for example, pack the product in boxes at an ergonomically correct working height and avoid incorrect lifting and turning.

The use of course varies depending on the type of hydraulic lifting solution, for instance, if you buy a work platform for lifting the employee in height, a goods lift for goods transport between levels or a loading bay that adjusts the height between loading dock and lorry.

Reduced physical strain has been proven to increase productivity, and working conditions improve, giving happier employees.

See a video about scissor lifts and your accessory options

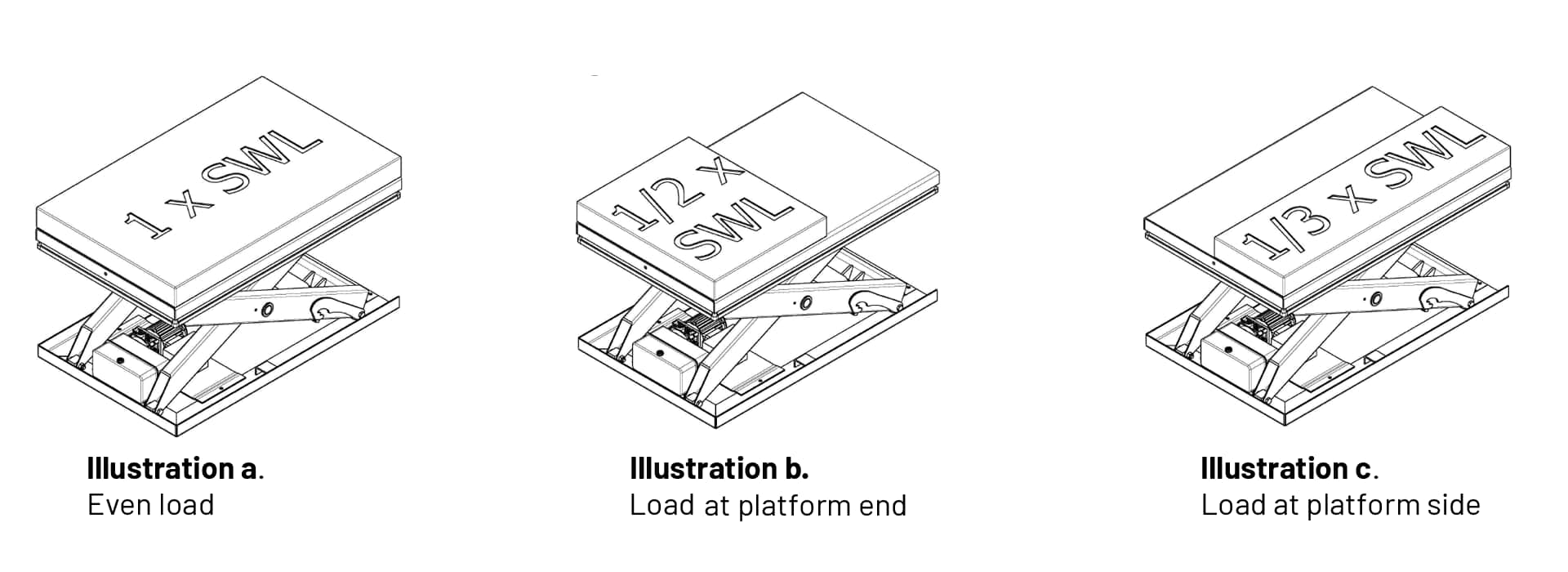

If you only load the table on one end of the table the capacity will be adjusted downwards by 50% (figure b) and you will be able to lift 1000 kg. When the table is only loaded on the side the capacity is reduced by 33% and the lifting table or scissor lift can then lift approximately 666 kg (figure c).

If you only load the table on one end of the table, the capacity will be adjusted downwards by 50%, and you can now lift 1000 kg. Is the platform loaded one the side the capacity is reduced by 33%, and the lifting table can thus lift approx. 666 kg.

NOTE: Words underlined with red are links and ones underlined with both red and white are hover pictures.

We know that every lift table is unique and therefore we have plenty of various accessories that can be added to your lifting table to fit it to your specific workstation and optimize your workflow. For example, you might have a lifting table that needs to be secured on two sides; or want photocell control on the table so that it adjusts in height according to how many boxes are on it; or maybe you need to be able to move the table around because your work often change.

Here are some of the more popular options:

You can see all the options for accessories here and call us at +45 9886 4900 if you are looking for anything specific.