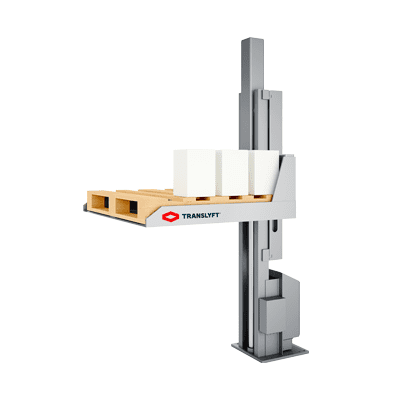

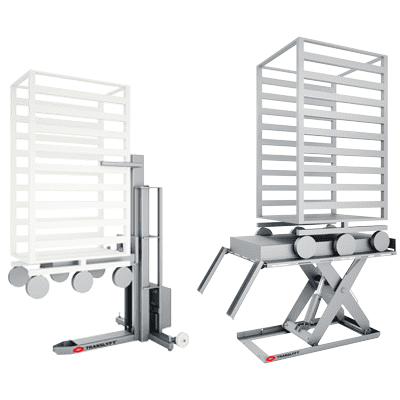

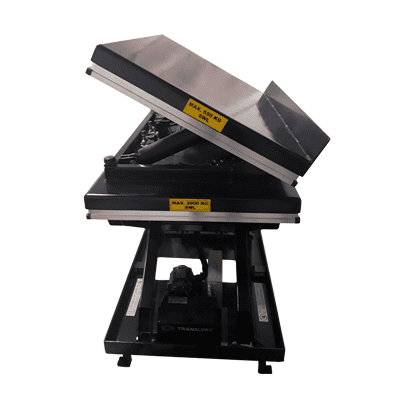

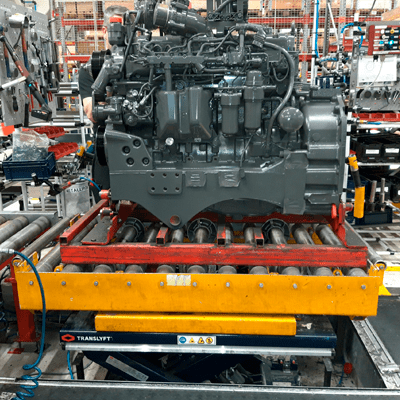

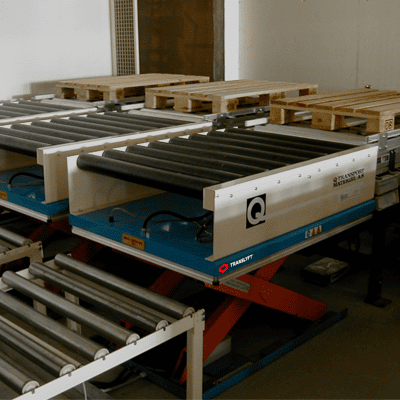

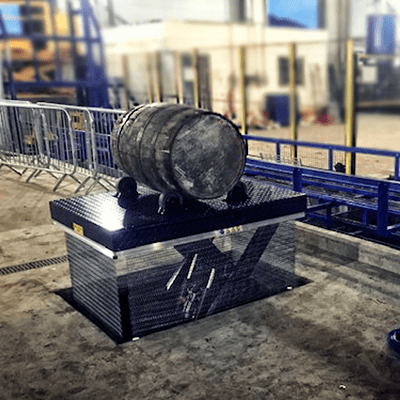

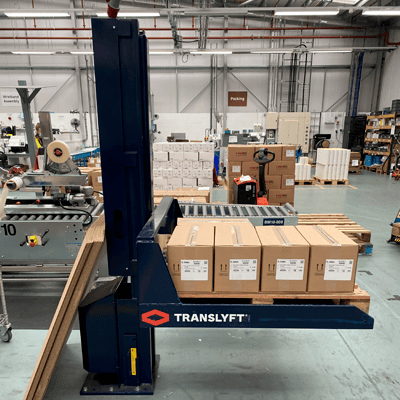

Scissor lift table

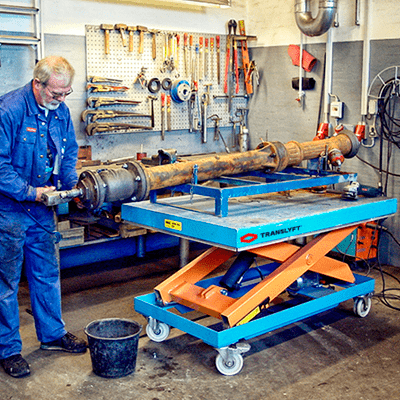

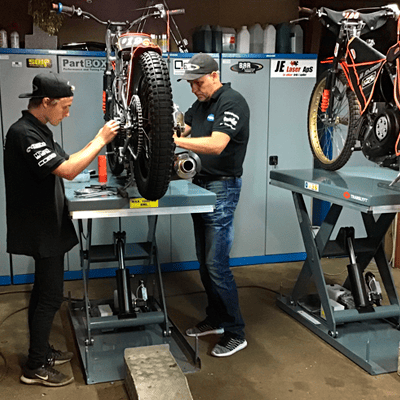

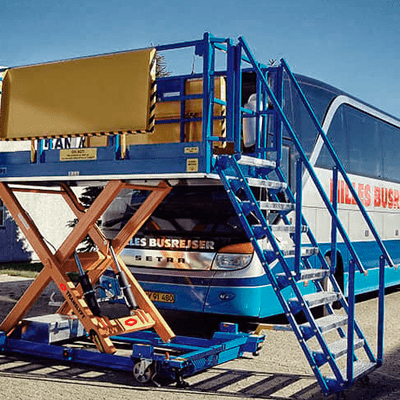

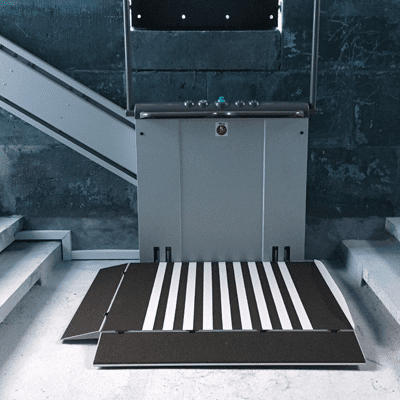

The scissor lifts are lifting devices aimed to elevate or lower objects to the desired height. They are equipped with a work platform, allowing the operator to place various objects on the top of it. The scissor lift name comes from the arms that holds the construction, running parallelly, resembling a scissor. The lifting table is a necessity for each workplace dealing with any lifting-related operations.

Advantages of a scissor lift

The advantages of a scissor lifts are many and include better safety, improved work environment, increased productivity, and a happier workforce. Moreover, a scissor lift table is very durable, and a lot of our customers return for spare parts more than 20 years after they have purchased a lifting table from TRANSLYFT.

Call us to hear more about the advantages at +45 9886 4900 or send a mail to sales@translyft.com

See how we can adjust a scissor lift to your demands.