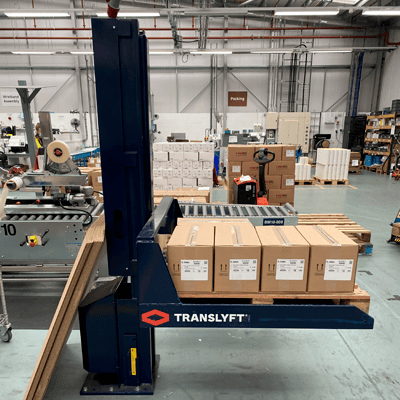

Find the right stainless steel solution

It is not easy finding the right lifting product for food, drinks, pharma and cleanroom environments.

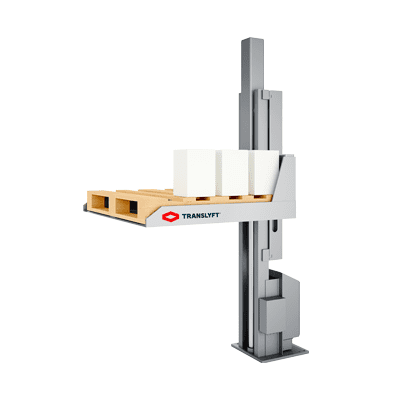

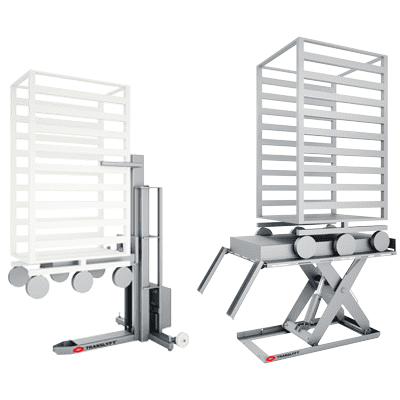

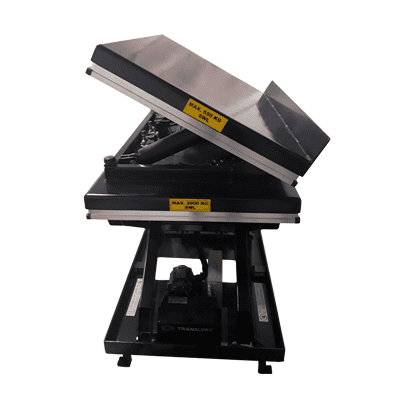

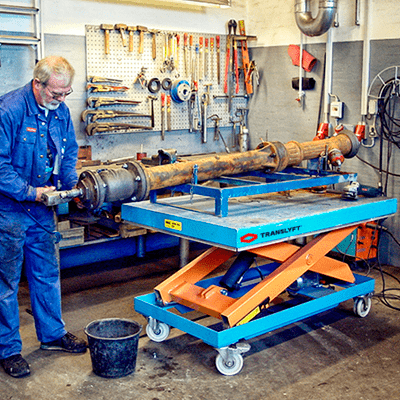

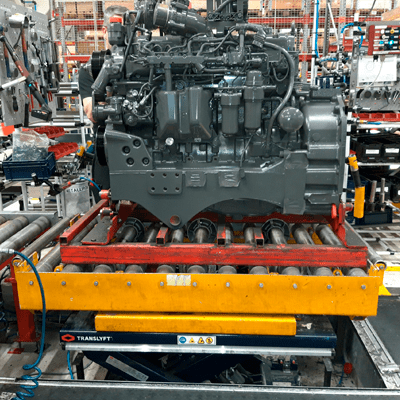

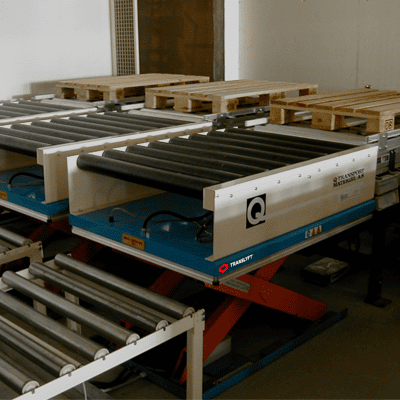

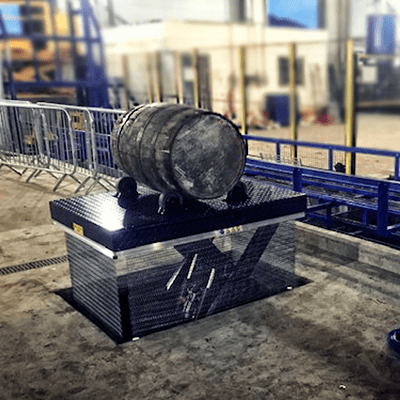

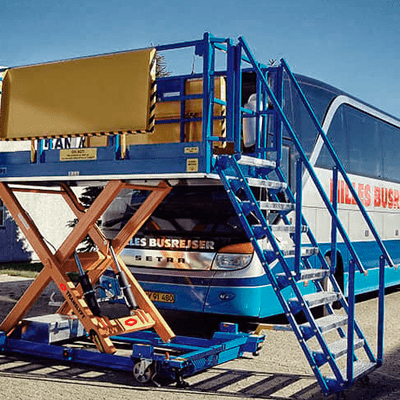

Firstly you need to establish which level of hygiene is needed for the workspace (see picture above). Depending on where in the production facility you are there are several options. In reception and dispatch a painted model is likely to do the job while a lifting table in the middle of the production line would often call for a stainless steel or Hygienic Design solution.

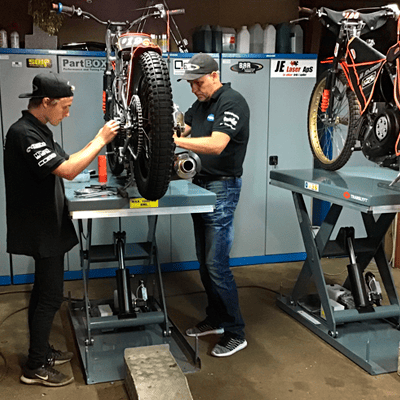

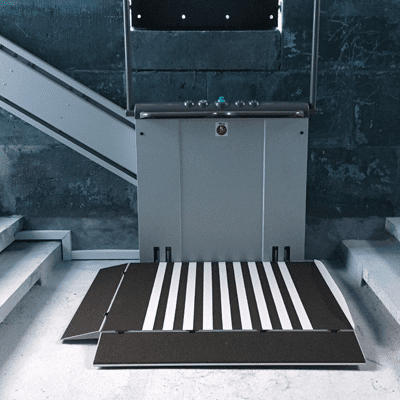

Then there are regulations to take into consideration. Contamination risks are a no-go and the products ability to be cleaned is very important. Furthermore, there is the need for ergonomic solutions to make sure that the employees are taken care of.

The product needs to be hygienic and corrosion resistant as well as reliable, safe and strong. And these are just to mention a few of the considerations to be handled. Luckily Translyft has more than 50 years’ experience with lifting solutions for these industries.