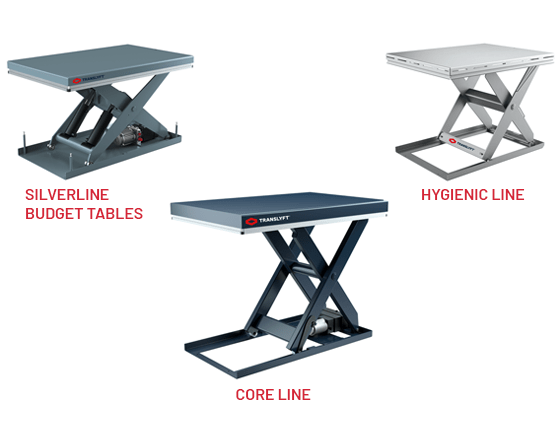

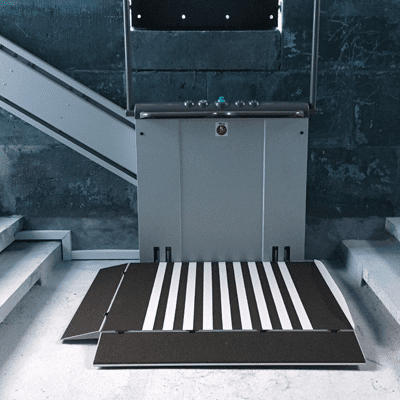

Scissor lifts

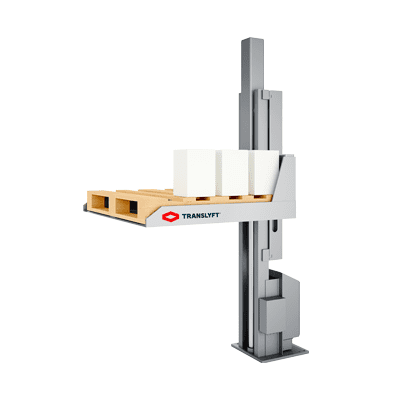

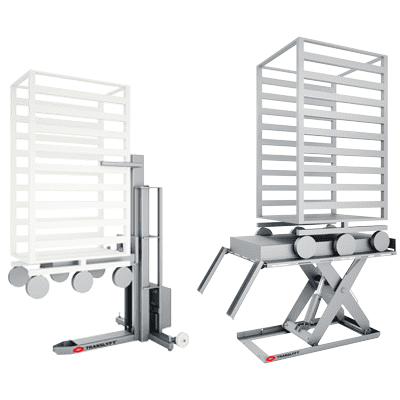

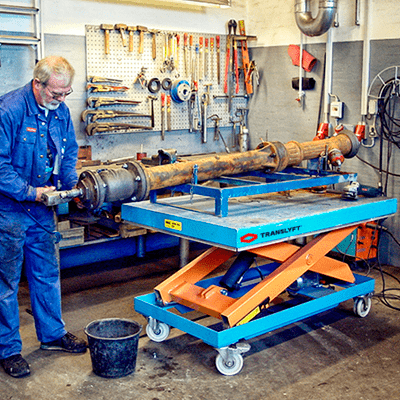

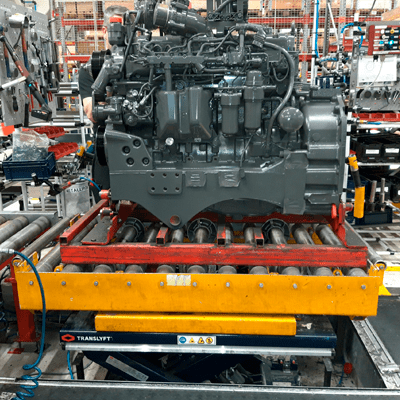

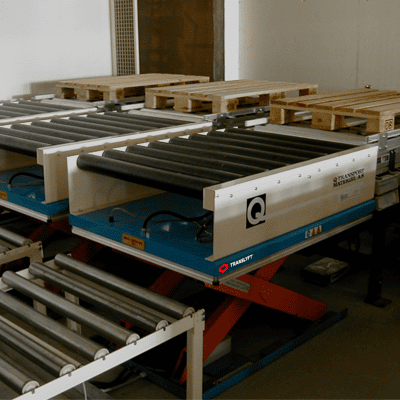

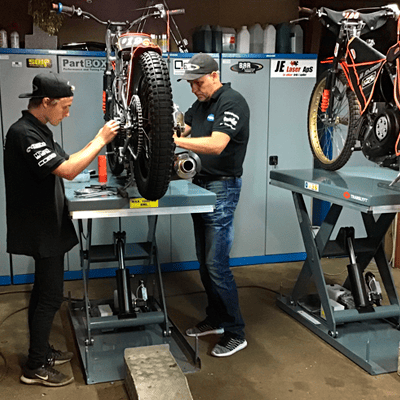

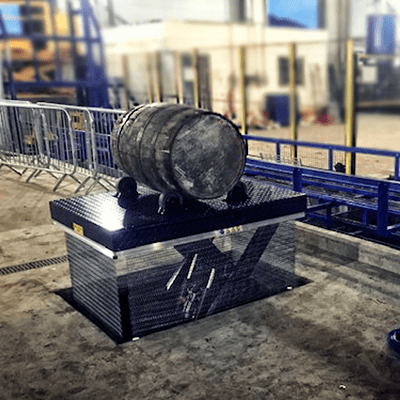

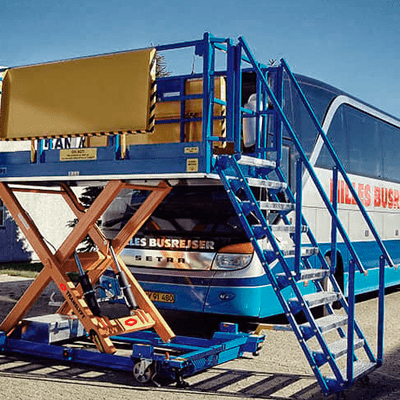

Scissor lifts cover a very broad range of lifting equipment, which are all distinguished by using folded supports arranged in a pattern similar to a scissor formation to elevate a platform to position either people or equipment in the right height and place. Scissor lifts can be used for a very wide range of applications across a multitude of industries. A substantial amount of these are used as aerial work platforms in the construction industry or for service and maintenance work.

Scissor lifts compromise over 20% of the total aerial work platform market and holds a total value of app. $ 2 billion. Due to the increased focus on user safety, efficiency, and general workplace improvements the market is forecasted to grow to $ 3 billion in 2026.

See what a scissor lift is.

.jpg)