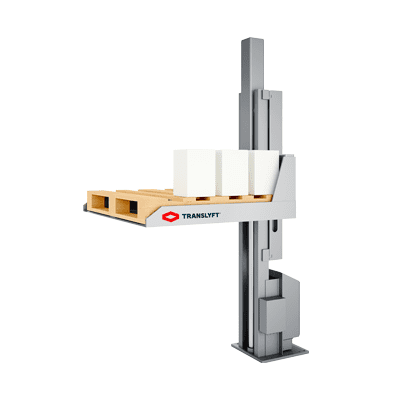

Goods Lift Increases Flexibility in Supermarket

A Large Danish Supermarket in Aarhus, Denmark, was looking for a goods lift to transport empty packaging such as cardboard and plastic. The lift needed to fit into an existing setup. Translyft provided a lift that optimized both safety and flexibility.

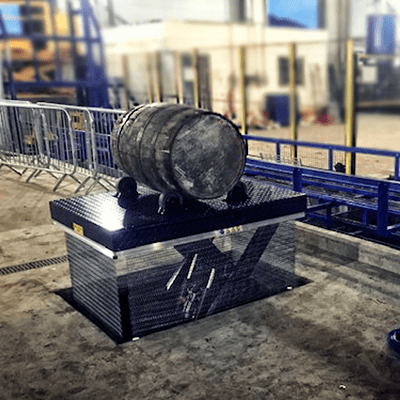

/Case_billede_kvickly_lift_uden_læs.jpg)

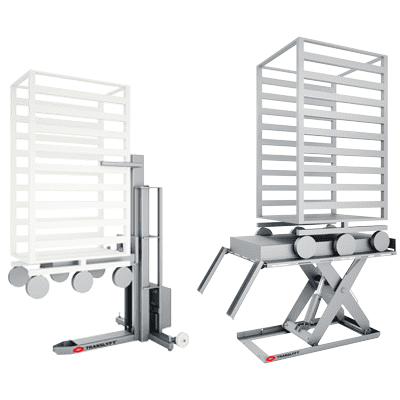

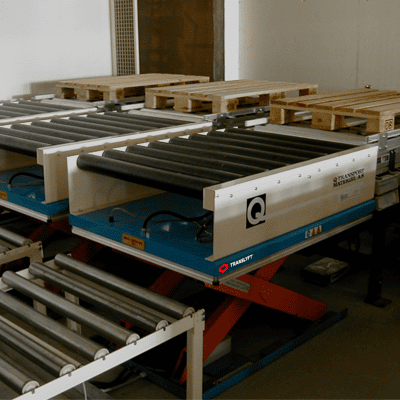

The Challenge

The supermarket initially had a setup with two docks at their goods reception area, but it was not a safe solution for employees, and the setup meant that only employees with a forklift certificate could retrieve goods materials on the docks.

Previously, employees would place filled pallets with cardboard or other packaging on the edge of a ramp, and then they would need to find an employee with a forklift certificate to move the waste down from the dock. This resulted in a lot of lost time.

Therefore, they wanted a lift table that was secure, so all employees could operate it, and the logistics of removing, for example, cardboard packaging and compacted returnable plastic packaging were minimised as much as possible.

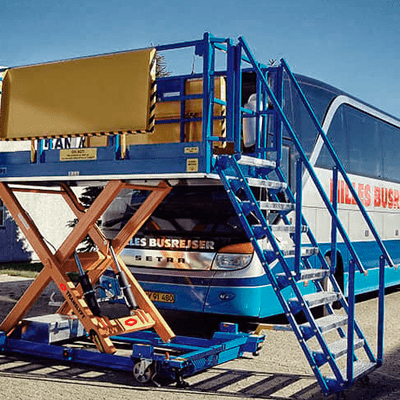

/Case_billede_kvickly_produkter_køres_på2.jpg)

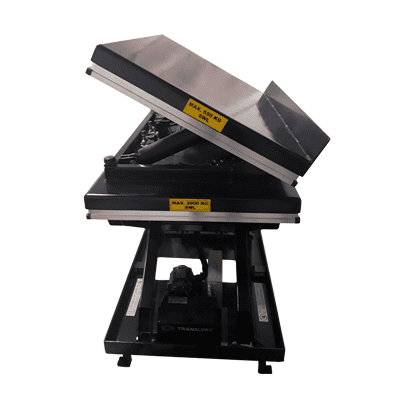

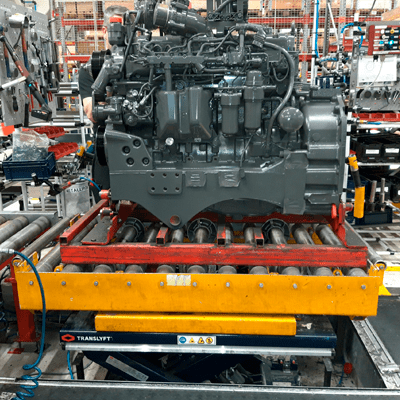

The Solution

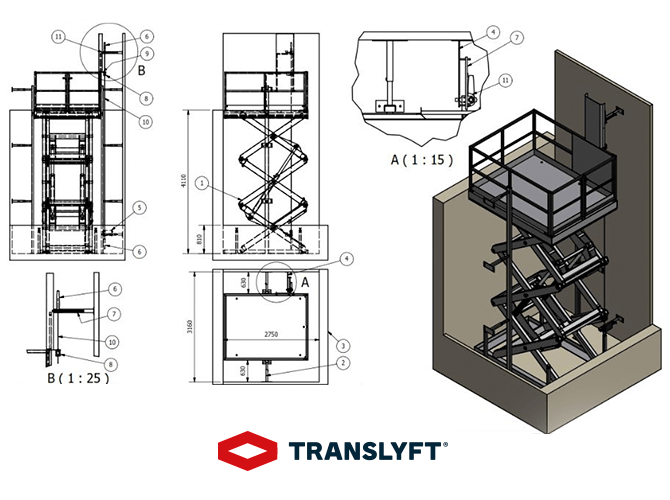

Translyft provided a lifting solution that ensured the highest possible safety for the employees. There are gates with interlocks that ensure the lift table can only operate when the gates are locked. Due to the lifting table's location in a public place, a net was installed on one open side of the lift table to prevent anyone from getting caught in the scissor mechanism. When the table is in the lowest position, a goal post ensures a natural barrier for passing employees, so they do not fall onto the lift.

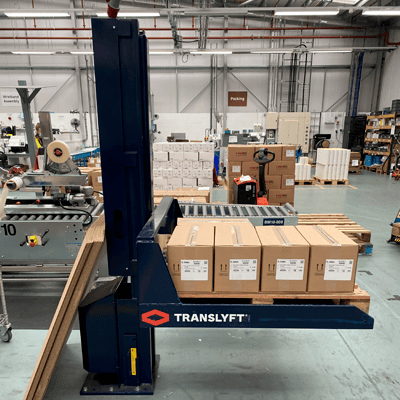

/Case_billede_kvickly_lift_køres_mod_bund.jpg)

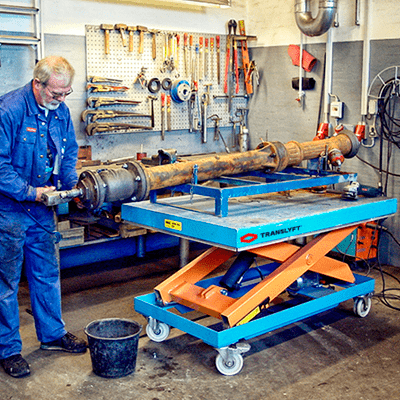

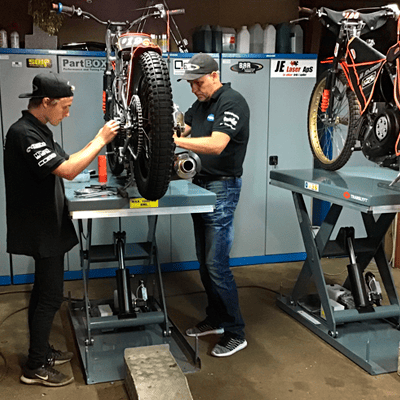

The Result

The warehouse now has a safe goods lift that operates several times a day. It has given more freedom to the employees, all of whom can now move the waste all the way to the destination point themselves. Forklifts are no longer used, and as a result, the forklift has been sold.

"The lift has eased logistics, significantly increased flexibility, and improved the working environment," says Dennis Andersen, Store Manager, Kvickly Bruuns Galleri.

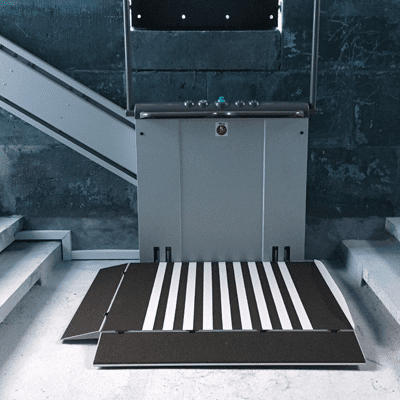

/Case_billede_kvickly_lift_åbnes.jpg)