Get data sheet for loading bays

| Capacity: | 500 - 6000 kg |

| Travel: | 550 - 2000 mm |

| Closed height: | 160 - 550 mm |

| Length: | 900 - 5000 mm |

| Width: | 650- 3000 mm |

| Galvanized | |

| Stainless | |

| Painted |

Available in ATEX

Available in ATEX Available in ATEX

Better Levelling

Better Levelling Better Levelling

Increased lifting capacity

Increased lifting capacity Increased lifting capacity

| Type | Capacity (kg) | Travel (mm) | Closed height (mm) | Total raised height (mm) | Length (mm) | Width (mm) | Lifting time (sec) | Motor (kW) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| TM 1500 | 1500 | 1100 | 230 | 1330 | 1700 | 900 | 27 | 0.75 | 315 |

| TT 3000 R | 3000 | 1600 | 350 | 1950 | 2500 | 2000 | 35 | 2.2 | 950 |

| TS 2000 | 2000 | 1500 | 250 | 1750 | 2200 | 1200 | 35 | 580 | 580 |

| TP 6000 | 6000 | 2000 | 500 | 2500 | 3100 | 1500 | 75 | 4 | 1600 |

A TRANSLYFT loading bay can be described as a platform equalizing the height difference between an unloading/loading vehicle and the warehouse floor. The loading bays are designed and equipped to handle large loads.

The loading bay is built for heavy loads and allows for fast loading and unloading of the goods. The entire delivery of goods can be loaded or unloaded in a few operations which saves a great deal of time.

Loading bays are suitable for e.g:

Our loading bays can be manufactured in ATEX, Hygienic Design, galvanized steel, stainless steel and painted steel.

Open yards, a bank, a dock, a warehouse and any other facilities receiving or distributing are all possible locations where a loading bay could be useful.

The potential use includes loading and unloading trucks or containers, handling goods and pallets, multi-height vehicle docking, roll cage as well as handling any delivery related activities by various delivery sites, buildings without raised docks, basements, staircases and warehouses. Suitable for any difference in levels, supports any vehicle size from a small van to a big lorry which is why the loading bay is manufactured to your specific demands.

Do you want more general information about a loading bay? Then click here: What is a loading bay.

A lot of accidents happen each year during the loading and the unloading of lorries. A bridge plate or a docking station only fulfil the purpose of connecting the levels without assuring any safety from the sides. This leaves the operator exposed to a potential danger. Workers could fall resulting in minor to heavy injuries or even death .

That is why a loading bay is a much safer solution because it can be equipped with railings on both sides. If a bridge plate is needed to supplement the lack of one in the vehicle delivering goods, we can add gates that open to secure the sides of the bridge plate enabling a smooth and seamless process.

Having gates at both the front and the back of the loading bay allows easy access and flow of transported goods.

Forklifts, pallet lifters, roll cages and any other load carriers may be used safely as the loading bay has enough nominal load to support it.

Want to hear more about how we can secure your employees with a loading bay? Call us at 0870 904 7775 or fill out the box below and we will contact you.

Translyft loading bays also help optimise time resources when performing loading and unloading activities on site. It cuts down on numbers of operations necessary to complete the task. As a result of shortened dispatch time the vehicle downtime is also reduced resulting in optimized productivity level.

Our customers have already experienced the advantages of the loading bay, as you can read in the case below. The advised loading bay solution helped them to reduce the amount of processes needed to load and unload each of the containers arriving or leaving their site. Their accident rate also dropped considerably.

As all our products, the loading bay is supplied with all the necessary safety equipment such as safety trip bar to stop the lowering of the table when activated, hence preventing body parts from being trapped.

Different accessories such as chain mesh, roller blinds or bellow guards can be installed to protect the travel zone from unnecessary contact by restricting the possible access between the lowering machine and a person as well as prevent any kind of garbage from falling inside the pit.

It creates a restricted, safe working environment where the design itself combined with all the safety features prevent risk exposure to the greatest extend possible.

The product complies with all the safety regulations included in the EN 1570 standard regulation regarding lifting tables.

The TRANSLYFT loading bay is a bespoke solution that is built with the safety equipment needed to meet your specific needs and requirements. Whether your business is in need of a solution manufactured in stainless steel or Hygienic Design, especially when working in the medicine or food industry, or in galvanized steel, which is the most durable surface treatment for loading bays mounted outside, or a painted steel version all of these options are available upon your request.

Your loading bay can also be made in ATEX, which is an EU directive regarding hazardous products, explosive atmospheres and sites tackling explosive materials such as printing industries, chemical plants, woodworking areas, etc.

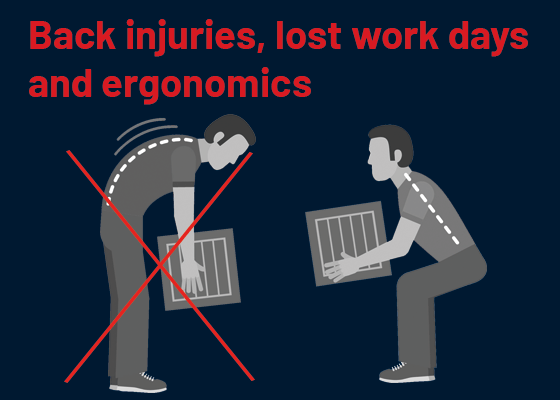

Lifting tables have been invented to ease physical work for employees, avoid injuries due to overload while increasing efficiency. Here you can read more about back pain, lost working days and ergonomics:

In addition to our standard 12 month parts and labour warranty we offer 3 after-sales service packages anywhere in the UK.

TRANSLYFT can deliver spareparts to all our lifting tables.

Whether it is a cylinder, oil or wheel that needs to be changed, we have it in stock so we can send it to you quickly. Write to our spare parts mail or contact us at tel. 0870 904 7775

Did you not find a product that fit your exact needs? TRANSLYFT are experts in both small and large adjustments of our products so please do not hesitate to give us a call and hear more.

TRANSLYFT can manufacture most products in stainless steel, galvanized steel and painted. Read more about the three surface treatments here